The do’s and don’ts of omnichannel inventory management

Creating an omnichannel business is no easy task.

As you add more channels, your focus on inventory management will need to increase – because in a highly competitive, customer-centred retail market, the way you manage your inventory can make or break you.

A proactive inventory system will result in happier customers and higher revenue, as well as less stress and fewer stock emergencies to solve. With a strong omnichannel inventory management system, you can rest easy knowing that your stock is where it needs to be.

Here are the key do’s and don’ts to consider to set your brand up for success.

Don’t segment your supply chain

Many retailers start with a thriving bricks-and-mortar store, then add an online store into the mix. It can be tempting to keep inventory for these streams separate, but segmenting your systems can cause all kinds of inventory visibility problems.

When you’re looking at two or more separate operations, it can be easy to miss a crucial step of the supply chain process – whether that be demand forecasting, supply chain optimisation, or space planning.

These gaps in the supply chain become problematic when it comes to order fulfilment, and can cause delays in delivery or allow customers to order out-of-stock items. A traditional inventory management system won’t be able to keep up with the modern retail landscape.

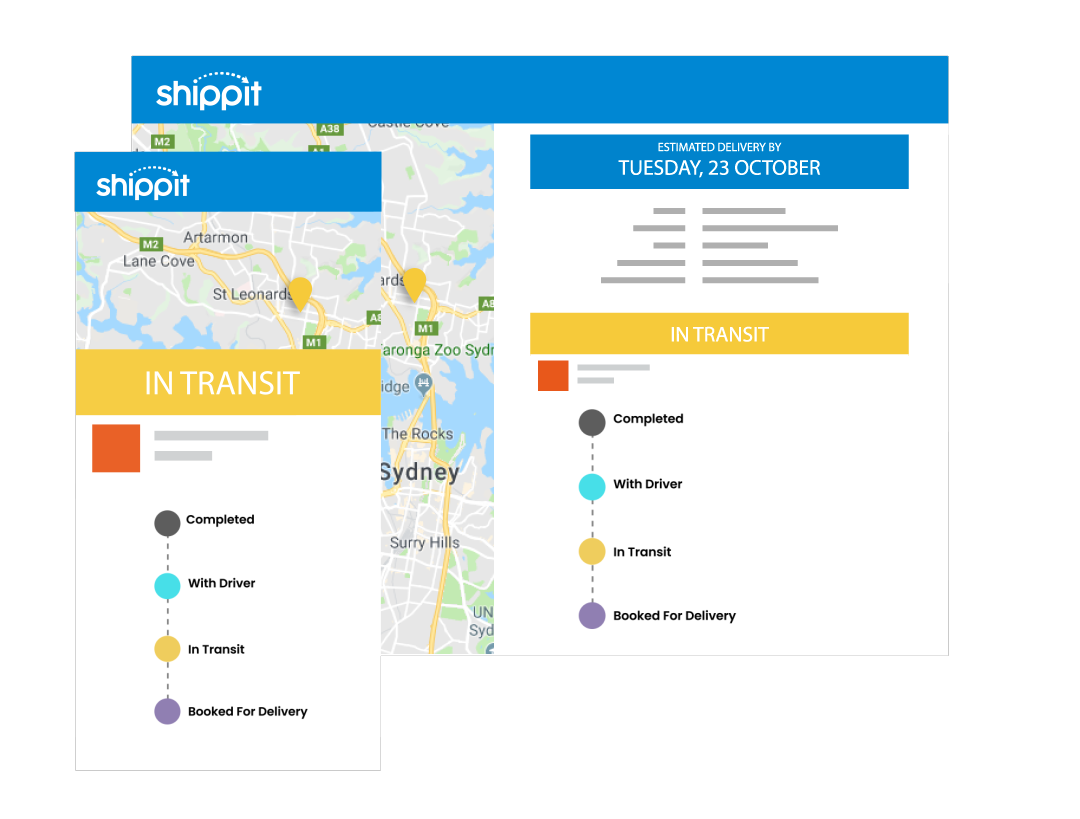

With an optimised warehouse management system or inventory management system, you can get super clear on where your inventory is at, and then use this as a predictor for future demand. With real-time syncing and order fulfilment across all channels, each order you receive can trigger the closest distribution centre and the most efficient shipping solution.

Do get the stock sweet spot

Too many businesses invest too much money in safety stocks. You don’t want to run out of an in-demand product, but you likewise don’t want to lose revenue on items that don’t sell.

A quick Google search will return tonnes of theories on how to set safety stock levels, as well as the mistakes, pitfalls and miscalculations you’ll need to be aware of. Finding the sweet spot for safety stocks can feel like a never-ending process, but it’s an absolutely vital area to invest your time and money into.

Whatever formula you decide to use, make sure you take into account your product’s demand and lead time. Consider holidays that may affect your supplier or shipping, and continually monitor and adjust your calculations to accommodate seasonal and promotional changes in demand.

Don’t stick to single-echelon inventory control when you grow

Moving from single-echelon to multi-echelon inventory management as your business grows is an important concept, but too many companies neglect to upgrade from the simple system that has previously worked from them.

Many small companies operate within the single-echelon space without a second thought – after all, single-echelon inventory control focuses on determining the appropriate level of inventory for an individual unit within the supply chain network.

But when you grow and add more pieces to the puzzle, you need to step away from this single-tier mode of thinking. Upgrade to a multi-echelon inventory system that takes a holistic, whole-of-operation approach by focusing on the correct levels of inventory across the entire network.

This way you can avoid workarounds, reactive patchwork fixes, and unclear inventory visibility to ensure a smooth fulfilment operation.

There are two main strategies for achieving multi-echelon. One option is strategic, which involves restructuring the business based on geographic, facilities, inventory and labour requirements. The second option is to take a tactical path to align systems, processes and data with targets and metrics for each stage.

Do think about returns

Any retailer, regardless of size, should know the importance of returns when it comes to customer satisfaction and retention.

When you grow to embrace omnichannel, you’ll need to make sure your returns logistics do too. You may want to allow items to be returned to different locations or online purchases to be returned in store. Whatever your conditions, there will be costs in terms of extra labour, evaluation and repackaging – but returns are not something you can ignore.

You’ll need a strong system in place to reduce the burden on your resources. You can do this by streamlining your repacking process, and implementing a detailed, well-communicated returns policy. You can also look into a shipping platform that handles returns for you.